What is MTP?

Introduction

The Module Type Package (MTP) is a standard developed by organizations such as NAMUR (User Association of Automation Technology in Process Industries) and ZVEI (German Electrical and Electronic Manufacturers' Association). MTP provides a framework for creating and integrating modular automation systems, allowing different process modules, irrespective of their manufacturer or underlying technology, to communicate and work together seamlessly.

At its core, MTP is about interoperability and flexibility. It defines a standardized interface for process modules (equipment or software), enabling them to be integrated into a larger process control system quickly and efficiently. This modular approach contrasts sharply with traditional monolithic systems, where custom integration is often required for each component, leading to increased complexity, cost, and time.

How Does MTP Work?

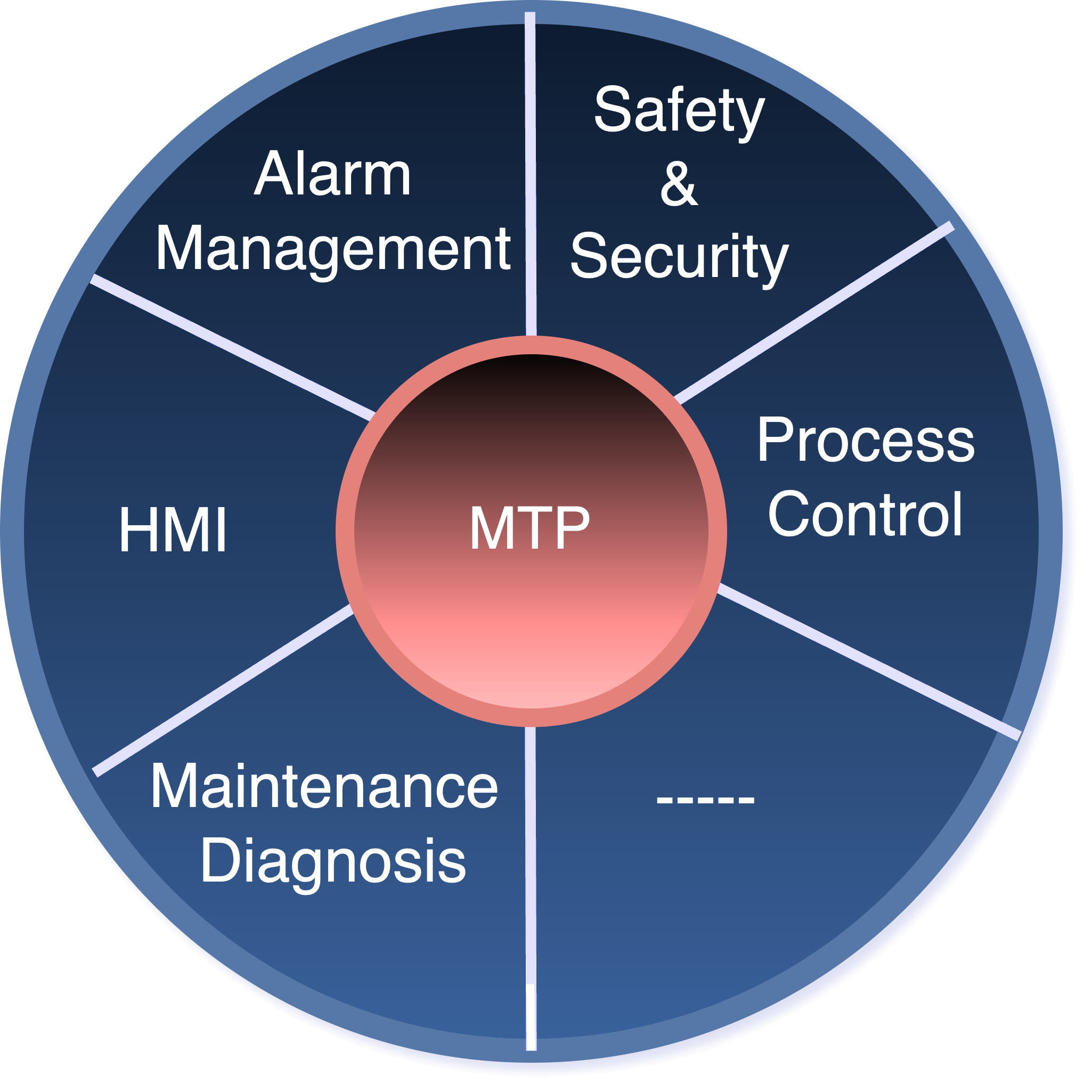

MTP works by encapsulating the process module’s functionality, including its automation logic, human-machine interface (HMI), and communication protocols, into a standardized package. This package can then be imported into a process orchestration layer (POL), which acts as the supervisory control system. The POL manages the interaction between different modules, allowing them to work together as a cohesive unit.

Key Elements of MTP:

- Services: Basic functions the module can perform, such as starting or stopping a pump or heating a reactor.

- Parameters: Configuration settings for the module, such as temperature setpoints or flow rates.

- Events: Notifications or alarms generated by the module, which can be communicated to the POL or an operator.

- HMI Information: Graphical representation of the module and its controls, which can be integrated into the overall system's HMI.

By standardizing these elements, MTP allows modules from different vendors to be plugged into the system with minimal custom integration.

Benefits of MTP for the Industry

- Increased Flexibility: Enables manufacturers to design and deploy modular systems that are easily reconfigurable, especially useful in industries like pharmaceuticals and specialty chemicals.

- Reduced Time-to-Market: Faster system integration and commissioning reduce the time needed to bring new processes online.

- Cost Savings: Less need for custom integration and greater reuse of existing modules lower system design and implementation costs.

- Vendor Independence: Promotes a vendor-agnostic approach, enabling companies to choose the best modules for their needs without being locked into a specific vendor’s ecosystem.

- Simplified Maintenance and Upgrades: Standardized interfaces make it easier to maintain and upgrade systems with minimal disruption.

- Enhanced Interoperability: Ensures effective communication between modules, regardless of underlying technology or manufacturer.

How MTP is Transforming the Industry

Pharmaceuticals and Biotechnology

MTP is enabling more flexible production processes, allowing companies to scale up or down, switch between different product lines, and integrate new technologies without disrupting existing operations.

Chemical Processing

The chemical industry benefits from improved safety and reduced implementation time. Modular plants can be designed with built-in redundancy and fail-safes, enhancing overall operational reliability.

Food and Beverage

MTP helps streamline production lines and maintain stringent quality control, allowing for rapid changeovers and consistent product quality.

Conclusion

The MTP standard represents a significant step forward in industrial automation. By enabling modular, flexible, and interoperable systems, MTP helps industries innovate faster, reduce costs, and respond more effectively to changing market demands.

Industries that embrace MTP today will be well-positioned to lead in the future, benefiting from agility, cost savings, and enhanced operational performance.